Contact:Mr. Pan

Mobile phone:+86 13928928158

Tel:+86 020-82620758

Add:Room 1601, Building 12, Innovation Center, Zengcheng Low - carbon Headquarters New Town, No. 400, Xincheng Avenue, Zengcheng District, Guangzhou City

Accurate temperature control: Key processes on the production line, such as frying and syrup boiling, are equipped with high-precision temperature control systems. The frying temperature is strictly controlled at 155 ℃ -170 ℃ to ensure that Sachima's fried blanks can be evenly heated to achieve the ideal crisp mouth.

When the syrup is boiled, the temperature is controlled at about 110 ℃ to make the syrup reach the proper viscosity and sweetness, providing stable sweetness and cohesiveness for Sachima.

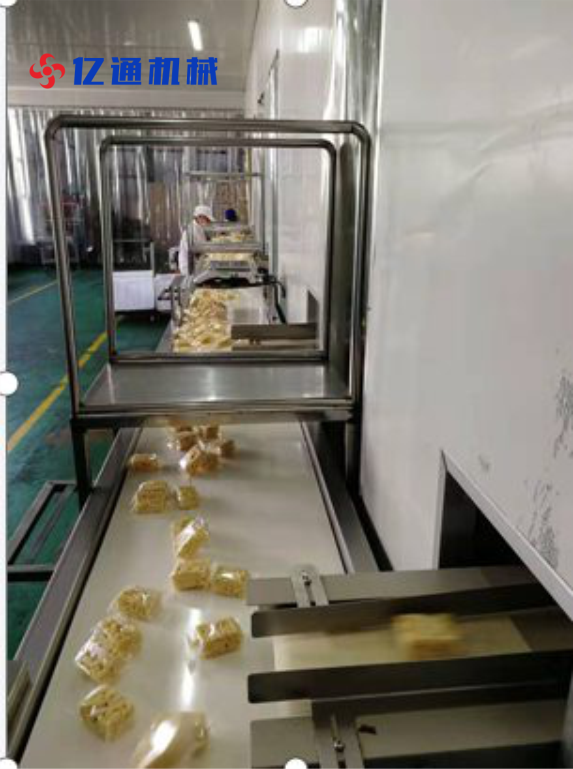

Standardized process flow: From raw material ratio to finished product packaging, the entire production process is strictly carried out according to standardized procedures.

For example, there are clear parameter requirements for the fermentation time, temperature, and humidity of dough, such as a fermentation temperature of 32-36 ℃, humidity of 80% -90%, and a fermentation time of 1 hour.

This standardized process ensures the consistency of taste and quality of each batch of Sachima.

Intelligent device application: Intelligent devices on the production line can monitor and adjust production parameters in real time. An online visual inspection system can instantly identify quality issues such as product defects and dimensional deviations,

And adjust production parameters in real-time to optimize product quality.

In addition, the predictive maintenance system predicts equipment failures through data analysis and carries out maintenance in advance to ensure that the production equipment is always in the best state and avoid production fluctuations caused by equipment failures, so as to ensure the stability of Sachima's taste.

Copyright © Guangzhou Yitong Food Machinery Equipment Co., All rights reserved. Record-filing number:粤ICP备2024336814号-1